what is Clean-out Block

What is Clean-out Block?

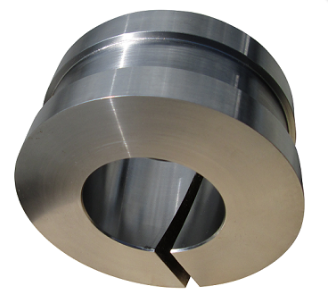

Extrusion machine is assembly by many parts, one parts is clean- out block, this part is designed to provide maximum cleanness on the liner wall.

The clean out block has a long structure in order to fit on the loader and enough to move freely along the liner. The size change control of the clean-out block, designed to be used at room temperature, is able to be performed easily. The block is lightened by manufacturing this with a hole centre and converted flexible by a precise channel cut.

Upon indication of the minimum liner diameter at room temperature and the operating temperature by the customer, we calculates the effect of the heat on both the dummy and the liner block and manufactures the cold clean-out block at the most appropriate size.

The size of the clean-out block needs to be calculated separately for each container and maximum aluminium film layer needs to be removed without harming the liner wall.

Which machine tools can make the Clean-out Block?

the clean-out block can be processing by Taiye CNC lathe for roughing and finishing, the CNC vertical machining center can milling and drilling the block, and our wire cut EDM machine can be cutting the small parts.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace