Do you know the spindle accelerator for machine tools?

Spindle accelerators is also called the growth of the handle, including gear type speed increaser and ultra-high speed pneumatic speed increaser, you can imagine, when the gear and bearing run at 40,000 and 160,000 and control the runout accuracy in 0.01mm or even 0.001mm, its manufacturing accuracy and heating and dynamic balance control is particularly critical!

Spindle speed increaser device is more common through the standard handle interface (such as BT/HSK/DIN/ISO etc.) installed in the machining center spindle output conical hole, there are also through THE VDI/BMT interface installed in the CNC turning center / CNC lathe power tool tower or heavy milling head by flange or automatic tension mechanism installed in the boring and milling machine.

There are several types of common spindle accelerators:

1, gear spindle speedup: general high speed up to 42000RPM, runout accuracy is generally 0.01mm;

2, ultra-high speed pneumatic accelerator: high speed up to 160000RPM, runout accuracy 0.001mm; There are mainly European and Japanese and South Korean products, generally Japanese and South Korean products power is very small, only dozens of watts, European products power can reach more than a kilowatt;

3. Motorized spindle speeder.

Spindle speeder for the machine type:

Spindle accelerators can be installed in machining centers, CNC turning centers, boring and milling machines and other machine tools, pneumatic accelerators (pneumatic spindle) and electric accelerators or even machine hands.

Spindle accelerators make it possible for ordinary machining centers to perform high speed milling, engraving and hole drilling. The spindle speed booster mounted on the machining center can automatically change the tool like a special tool.

Main industries and necessity of using spindle accelerators:

1. Spindle accelerator is mainly used to increase the machine speed, making high speed cutting to achieve good finish, precision and improve processing efficiency, often used in precision mold, microelectronics, medical equipment, precision instruments, aviation energy and other fields;

2. Why do you need to use the speed increase: in the use of micro milling cutter and drill processing, the need to use a high speed to improve the surface processing quality, while greatly improving the processing efficiency, if the machine tool itself speed up to the requirements, you need to use the spindle speed increase;

3. In addition, the general heavy boring and milling machine speed is relatively low, usually add heavy spindle speed booster (speed milling head).

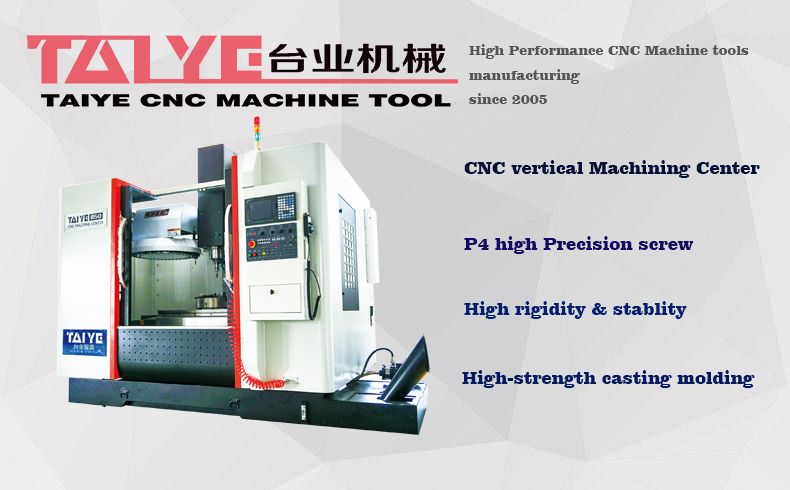

Taiye machine provide a full set of professional extrusion die equipment and extrusion dies, We have an aluminum extrusion die factory and a professional extrusion die equipment company in China. Our machine tools product include machining center, CNC lathe, wire cut EDM machine, EDM machine, Vacuum Furnace, etc., Each of taiye machines is professionally customized for the aluminum extrusion die process, with simple operation and high efficiency.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace