Features of CNC machining

CNC machining (computer numerical control machining), in simple terms, is to use the digital control system to complete the processing of the entire part on the processing machine. It also refers to a process method for processing parts on a CNC machine tool. The process rules for CNC machine tool processing and traditional machine tool processing are generally consistent, but significant changes have also taken place. A machining method that uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of variable parts, small batches, complex shapes, and high precision, and to achieve high-efficiency and automated processing. It is also a symbol of the development of the country's manufacturing industry.

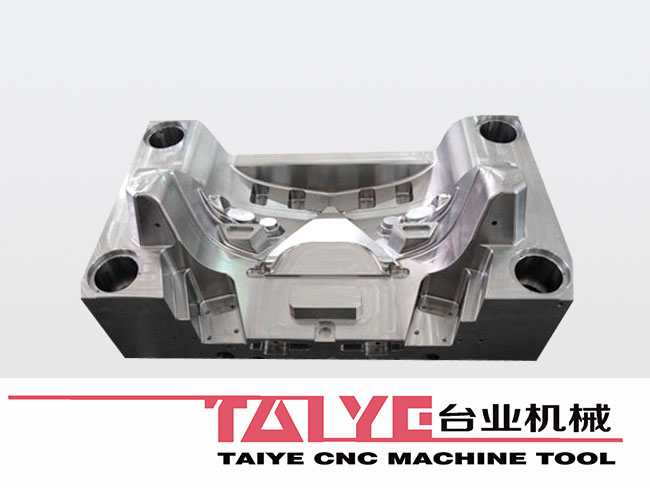

The biggest feature of CNC machining is the use of punched tape (or tape) to control the machine tool for automatic processing. Because airplanes, rockets, and engine parts have different characteristics: airplanes and rockets have zero parts, large component sizes, and complex shapes; engine zero, small component sizes, and high precision. Therefore, the CNC machine tools selected by the aircraft and rocket manufacturing departments and the engine manufacturing departments are different. In aircraft and rocket manufacturing, large-scale CNC milling machines with continuous control are mainly used, while in engine manufacturing, both continuous-control CNC machine tools and point-control CNC machine tools (such as CNC drilling machines, CNC boring machines, machining centers, etc.) are used . At the same time, CNC machining is also strategic in its role and status; it is technically comprehensive; it is real-time in control; it is domain-based in software (CAM software); it is adaptable in promotion and application; and in tracking. Lagging behind; openness in development. The important position and huge benefits of CNC technology and CNC machine tools in today's machinery manufacturing industry (turning and milling) have shown their strategic role in the modernization of the national basic industry, and have become the traditional machinery manufacturing industry to upgrade, transform and realize automation. An important means and sign of flexible and integrated production.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace