What is the difference between CNC engraving and CNC milling?

Both CNC engraving and CNC milling use the milling principle, what is the main difference between CNC engraving and CNC milling? The main difference is in the diameter of the tool used. The commonly used tool diameter range for CNC milling is 6-40 mm, while the tool diameter for CNC engraving is 0.2-3 mm.

Is CNC milling only for rough machining and CNC engraving for finishing?

Before answering this question, let's first understand the concept of process. The amount of machining in the roughing process is large, and the amount of finishing machining is small, so some people habitually regard roughing as "heavy cutting" and finishing as "light cutting". In fact, roughing, semi-finishing, and finishing are process concepts, which represent different processing stages. Therefore, the accurate answer to this question is that CNC milling can do heavy cutting or light cutting, while CNC engraving can only do light cutting.

Can CNC engraving be used for rough machining of steel materials?

To judge whether CNC engraving can process a certain material, it mainly depends on how big a tool can be used. The tool used in CNC engraving determines its maximum cutting capacity. If the shape of the mold allows the use of tools with a diameter of more than 6 mm, CNC milling is strongly recommended, followed by engraving to remove the remaining material.

Can the engraving process be completed by adding a speed-increasing head to the spindle of the CNC machining center?

Can not finish it. This product appeared at the exhibition 2 years ago, but it could not complete the engraving process. The main reason is that the design of the CNC machining center considers its own tool range, and the overall structure is not suitable for engraving processing. The main reason for this misconception is that they mistaken the high-speed motorized spindle as the only feature of the engraving machine.

CNC engraving can use small diameter tools, can it replace EDM?

cannot be replaced. While engraving reduces the range of tool diameters for milling, small molds that were previously only possible with EDM can now be achieved with engraving. However, the length/diameter ratio of engraving tools is generally around 5:1. When using a small diameter tool, only a very shallow cavity can be machined, and the EDM process has almost no cutting force, as long as the electrode can be produced, the cavity can be machined.

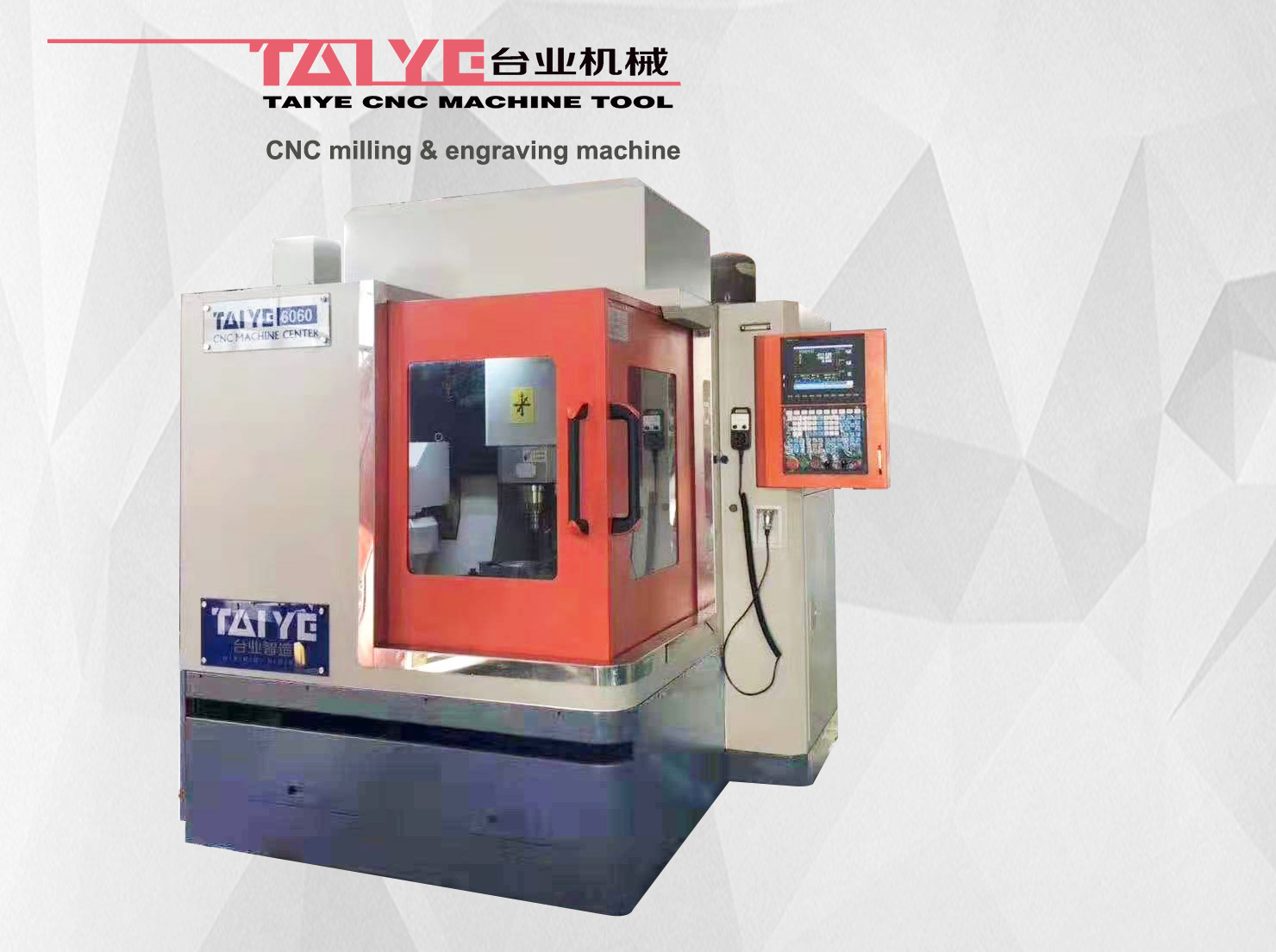

Taiye machine provide a full set of professional extrusion die equipment and extrusion dies, We have an aluminum extrusion die factory and a professional extrusion die equipment company in China. Our machine tools product include machining center, CNC lathe, wire cut EDM machine, EDM machine, Vacuum Furnace, etc., Each of taiye machines is professionally customized for the aluminum extrusion die process, with simple operation and high efficiency.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace