What is the difference between roughing and finishing in CNC machining?

CNC machining is generally divided into rough machining, medium machining, and finishing. The tool for finishing turning is a standard tool, and the workpiece will not have surface roughness when it is machined, and there is no place where the machining is not in place, and the tolerance size can be guaranteed. The rough cutters processed by CNC are different, the wear degree of the workpiece is different, and the machining accuracy (precision) is different.

When roughing, consideration should be given to leaving a sufficient and reasonable allowance for finishing.

During finishing, the correct datum plane positioning should be selected, and the reasonable processing sequence, tool material and cutting parameters should be selected to ensure the final quality of the product. CNC machining is a process method for machining parts on CNC machine tools. The process rules of CNC machine tool processing and traditional machine tool processing are generally consistent, but there have also been significant changes. For example, the mechanical processing method that uses digital information to control the displacement of parts and tools is an effective way to solve the problems of variable variety of parts, small batches, complex shapes, and high precision, and to achieve high-efficiency and automated processing.

The surface quality of CNC machined parts affects the use of parts, and parts with defective surfaces affect the performance of parts. In CNC machining, the control system issues instructions to make the tool perform various movements that meet the requirements, and the shape and size of the workpiece and other technical requirements and processing technology requirements are represented in the form of numbers and letters. In order to improve the degree of production automation, shorten the programming time and reduce the cost of CNC machining, a series of advanced CNC machining technologies have also been developed and used in the aerospace industry.

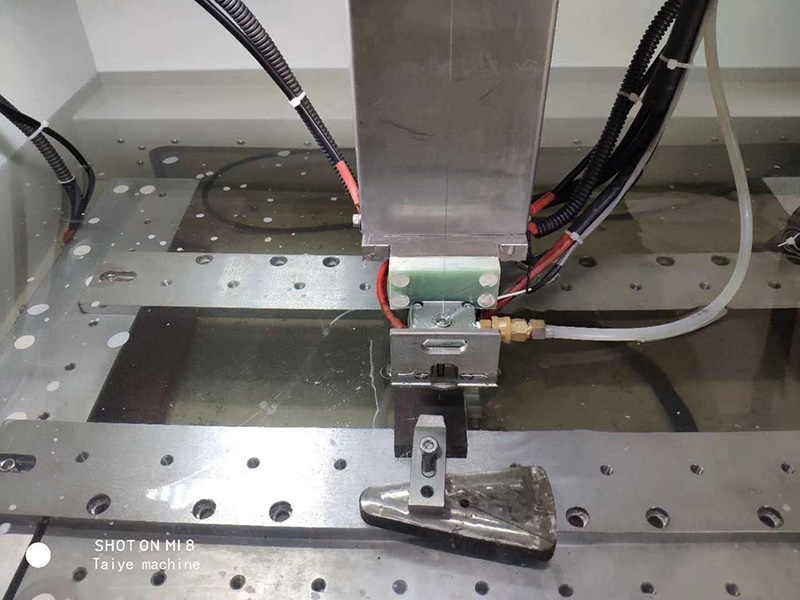

Taiye Machinery was founded in 2005, the company is located in the beautiful Zhejiang, China,Taiye machine provide a full set of professional extrusion die equipment and extrusion dies, We have an aluminum extrusion die factory and a professional extrusion die equipment company in China. Our machine tools product include machining center, CNC lathe, wire cut EDM machine, EDM machine, Vacuum Furnace, etc.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace