What level can the processing precision of Brass wire EDM machine reach?

We who do machining are no strangers to wire cutting EDM machine. Why do more and more people choose brass wire cutting processing nowadays?

The continuous improvement of precision, complexity, and long-life stamping die manufacturing accuracy and surface quality requirements have promoted the rapid development of wire cutting processing technology.

The higher processing efficiency of the current advanced brass wire cutting machine can reach 500 mm²/min. The processing efficiency of larger thickness workpieces has practical technical improvement. For example, when cutting 300 mm thick workpieces, the processing efficiency can reach 170 mm²/min. For the processing of workpieces with varying thickness, the thickness of the workpiece is automatically detected, and the processing parameters are automatically adjusted to prevent wire breakage and achieve higher processing efficiency in this state.

In addition, the fast automatic threading technology introduced by the advanced wire cut EDM machine tool, the automatic threading time is less than 15 s, which improves the efficiency of the processing operation; the double-wire automatic exchange technology for Wire EDM machine can automatically double Wire switching processing. Thick wire is used for the previous cutting, generally the wire diameter is 0.25 mm, to improve the processing efficiency, and can be cut without core; then the thin wire is used for trimming, generally 0.10 mm thin wire is used to cut small rounded corners. Improve the accuracy and save 30% to 50% of the cutting time overall.

The high-precision finishing circuit adopted by the advanced wire EDM machine tool is an effective technology to improve the straightness of the processed workpiece, which significantly improves the accuracy of thick parts processing; in order to carry out small fillets, narrow slits, narrow grooves and fine parts. The high-quality CNC wire EDM wire cutting machine can use 0.02~0.03mm electrode wire for cutting.

The wire cutting EDM machine adopts a closed-loop digital AC (direct) current servo control system to ensure excellent dynamic performance and high positioning accuracy. The processing accuracy can be controlled within a few microns, and the precise positioning can achieve 0.1μm equivalent control; adopts immersion processing , Reduce the thermal deformation of the workpiece; motor servo, closed-loop electrode wire tension control; voltage-modulated tool setting power supply to achieve high-precision tool setting, the tool setting accuracy can reach 0.002 mm, without damaging the workpiece, regardless of whether it is dry or wet.

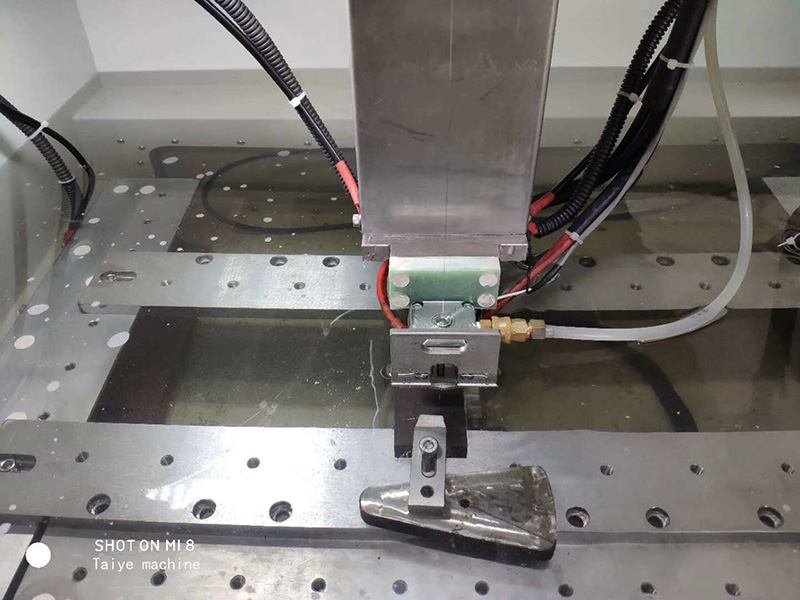

Taiye machine specializes in serving aluminum extrusion molds. We professionally provide a complete set of extrusion mold production equipment and tools, such as machining centers, wire cutting, various tools, etc., which are deeply trusted by customers. If you are interested, please contact us.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace