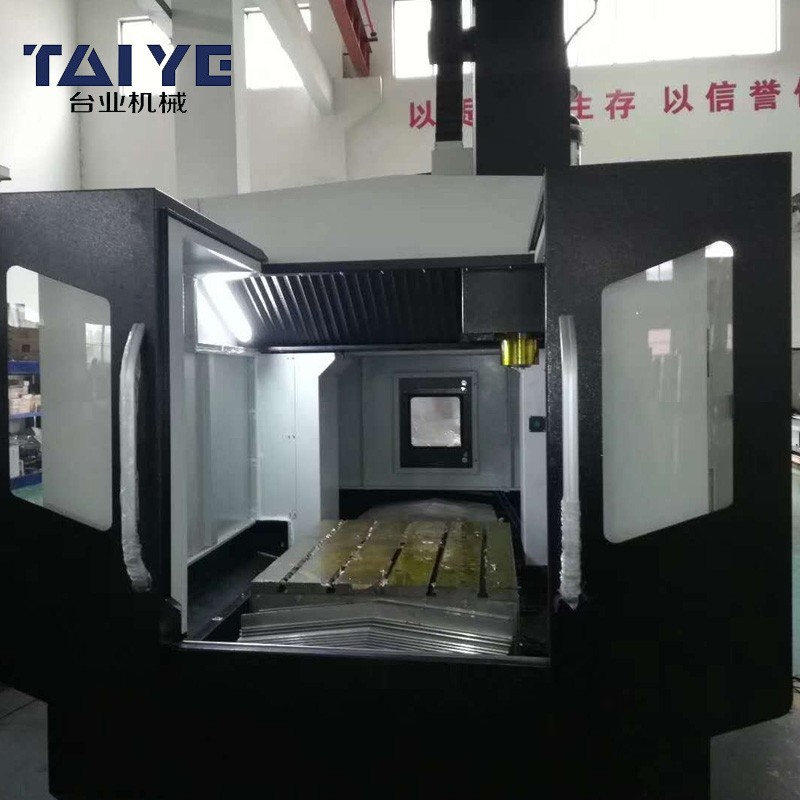

2140B Gantry Milling Machining Center For Mold Process

- TAIYE

- HANGZHOU CHINA

- 30 Days After Order Confirm

- 30 Sets Per Month

Taiye gantry machining center is widely used to produce the heavy duty auto spare parts, medical treatment instrument and any kind of injection mould, blowing mould, die-casting mould, car LED mould, toy mould and precise mould and so on

Taiye machinery company, more than 200 high tech talents and more than 2000 square meter production workshop and more than 15 years machine tool production R&D experience, our machine tool use taiye intelligent operation system, easy to use, each worker can operate 3 to 4 sets machine tool at the same time.

Taiye CNC machine tools are hot sale in southeast Asia, North Africa, south American, China mainland. our customer include JMA aluminum company, Fenglu aluminum company, Jiangshun group, Xingfa aluminum company, etc.

2140B Gantry Milling Machining Center For Mold Process

Machine Introduction

(1). Whole resin sand of high quality casting, after stress relieving and precision finish,key position use import components and install according to international standard.

(2). Our 3 axis precision grade high rigid line rail use HIWIN(Taiwan) or PMI,C3 grade precision double nuts ballscrew after pre –tight eliminate the intervals between axis,increase the transmission accuracy,make sure the favorable positioning accuracy and resetting accuracy of each axis.

This machine is suitable for machining each complex curved surface parts in machinery industry for its high efficiency and performance,especially for high precision mould.

(3). we use positive displacement oil distributor,timing and ration to supply oil to each lubrication housings,make sure the uniformity and lubrication of each lubrication surface,decrease slide grind resistance effectively.

(4). X,Y,Z three axis exchange servo motor contact precision ballscrew through high precision no backlash,ballscrew and bearing use high precision and rigid like group angle contact ball bearing.

(5). repeating accuracy:0.003mm.

2140B Gantry Milling Machining Center For Mold Process

| pecifications | Units | TY 2140 | |

| X-axis travel | mm | 4200 | |

| Y-axis travel | mm | 2500 | |

| Z-axis travel | mm | 1000 | |

| Worktable size | mm | 2100*4000 | |

| Max. load of worktable | kg | 12000 | |

| Number of T-slot | qty | 9 | |

| Width of T-slot | mm | 28 | |

| Distance between the adjacent T-slot | mm | 200 | |

| Distance between the two colums | mm | 2600 | |

| Distance from spindle nose to worktable surface | mm | 200~1200 | |

| Spindle taper | BT50 | ||

| Feed speed | X,Y axis | mm/min | 1~4000 |

| Z axis | mm/min | 1~2000 | |

| Rapid speed | X,Y axis | mm/min | 12000 |

| Z axis | mm/min | 8000 | |

| Spindle moter power | kw | 18.5/22 | |

| Spindle speed | rpm | 30~3200 | |

| Positioning accuracy X,Y,Z | mm | ±0.005 | |

| Repeat positioning accuracy X,Y,Z | mm | ±0.005 | |

Machine tool Configuration

| CNC system | Mitsubishi M80A/ FANUC |

| castings | Resin sand casting |

| Spindle | Taiwan Kunchun/Royal spindle |

| screw | Taiwan PMI/ HIWIN /4012 type |

| Knife cylinder | TAIWAN Chen Sound |

| The bearing | Japan NTN/NSK |

| Chip conveyor | Chain type Chip conveyor (Taiye) |

| Oil skimmer | Taiye Oil skimmer |

| Spindle Oil Cooler | Taiwan HABOR |

| Linear guide | Taiwan PMI / Germany INNA |

| Coupling | Germany R+W |

| Electrical equipment | Schneider |

Packing Details : general packing for seashipping

Delivery Details : 30 days after order confirm