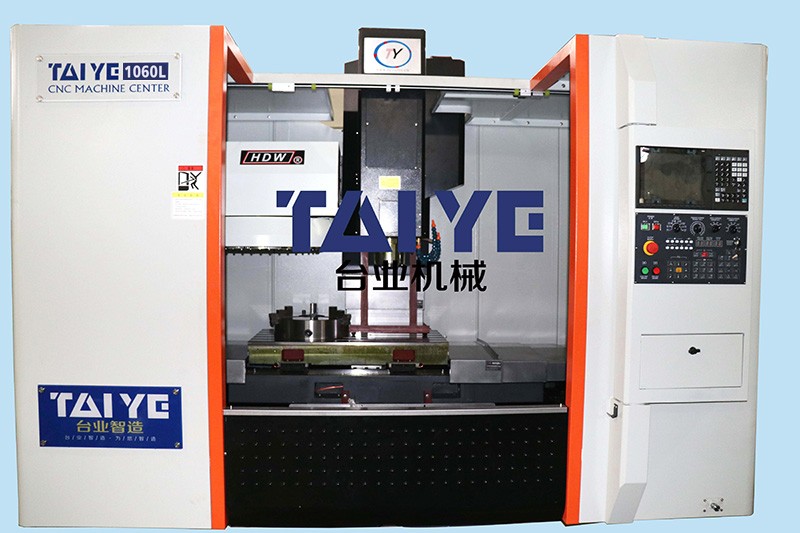

VMC 1060B 3 Axis Hard Line Vertical CNC Milling Machine For Aluminum Extrusion Dies

- TAIYE

- HANGZHOU CHINA

- 30 Days After Order Confirm

- 30 Sets Per Month

Taiye VMC 1060B, Max processing 1100*600 MM aluminum extrusion dies, The machine adopt taiye patented technology, high cost effective and easy to use.

Taiye CNC machine tool have more than 15 years high performance machine tool manufacture experience, special use in aluminum extrusion mold dies and metal machining industrial.

Taiye machinery company, more than 200 high tech talents and more than 20000 square meter production workshop. We have more than 10 machine tool software patent rights, which is make our machine tool have more competitive advantage

Taiye vertical machining center, hot sale in southeast Asia, north Africa, China mainland. our customer include JMA aluminum company, FengLu aluminum, Xingfa alumium company, etc.

VMC 1060B 3 Axis Hard Line Vertical CNC Milling Machine For Aluminum Extrusion Dies

Taiye VMC 1060B 3 axis hard line vertical milling machine is special use for alumium extrsuion dies processing, the machine tools can be max processing 1100 x 600 MM mold dies, and the machine adopt high rigidity and stablity bara machine, import brand spindle and screw, high quality accessories, won the trust and use of customers.

Main Features for VMC1060B

1) easy in installation and maintation.

2) world brand components parts.

3) Running in a high automatization and intellectualization,no pollution

Parameter for Taiye VMC1060B

1.The CNC system: Mitsubishi M80 | ||||||||

2.The high quality castings: Resin sand casting | ||||||||

3.The spindle: Taiwan famous high speed spindle 8000 RPM | ||||||||

4.The screw: TAIWAN PMI/ HIWIN | ||||||||

5.ATC: Robotic tool magazine ATC (HDW ) | ||||||||

6.The unclamping cylinder: Taiwan Shang product | ||||||||

7.Coupling :Germany R+W | ||||||||

8.The bearing: Japan NSK | ||||||||

9.Crawler chip conveyor | ||||||||

10.Electrical equipment: Schneider | ||||||||

11.The Internal protection: Total protection | ||||||||

12.After-sales Service:one year warranty and free component in guarantee time, we can sent our engineers to repair your machines | ||||||||

TY-1160B Hardrail Vertical Milling Machining Center | |

Table size (MM) | 1200*650 |

X-axis travel (MM) | 1100 |

Y-axis travel (MM) | 650 |

Z-axis travel (MM) | 700 |

X/Y/Z axis servo motor power | 3/ 3 / 4.5 KW |

Maximum table load (KG) | 1200 |

T-slot | 5-18X120 |

Spindle type | BT40 |

spindle speed | 12000 RPM |

Spindle power (KW) | 11/15 KW |

Rapid traverse (X/Y/Z) (mm/min) | 16000 |

Cutting feed (mm/min) | 2-8000 |

Spindle nose to table (MM) | 120-820 |

Spindle center to column surface distance rail (MM) | 740 |

Positioning accuracy (MM) | ±0.005 |

Repeat accuracy (MM) | ±0.003 |

line Rail type | X axis/ RGH45HA |

Maximum tool Number | 24T |

Maximum tool weigh (KG) | 6 |

Dimensions (MM) | 3350*2850*2650 |

Machine weight (KG) | 7000 |

Product Show