what is Turning machining

what is Turning machining

Lathe processing mainly uses a turning tool to turn a rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves and other workpieces with rotating surfaces. They are the most widely used type of machine tool processing in machinery manufacturing and repair factories.

Turning is a method of cutting the workpiece on the lathe by rotating the workpiece relative to the tool. The cutting energy of turning is mainly provided by the workpiece rather than the tool. Turning is the most basic and common cutting method, and it occupies a very important position in production.

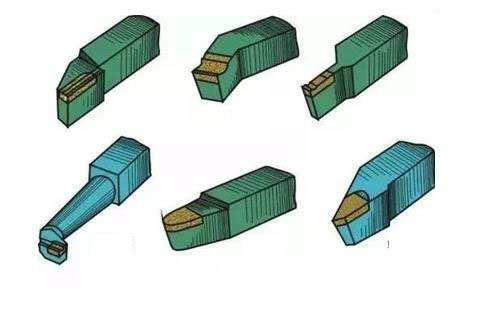

Turning is suitable for machining revolving surfaces. Most workpieces with revolving surfaces can be processed by turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and revolving forming surfaces. The tools used are mainly turning tools.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace