Brass Wire EDM Machine - Wire Cut EDM, Slow Speed Wire EDM Machine For Aluminium extrusion dies

- Taiye

- Zhejiang China

- 30 days after order confirm

- 30 sets per month

Taiye wire cut EDM machine is most widely used by the mold-making, tool, and die industries.

Taiye machinery company, more than 200 high tech talents and more than 2000 square meter production workshop and more than 15 years machine tool production R&D experience, our machine tool use taiye intelligent operation system, easy to use, each worker can operate 3 to 4 sets machine tool at the same time.

Taiye machine tools are hot sale in southeast Asia, North Africa, south American, China mainland. our customer include JMA aluminum company, Fenglu aluminum company, Jiangshun group, Xingfa aluminum company, etc.

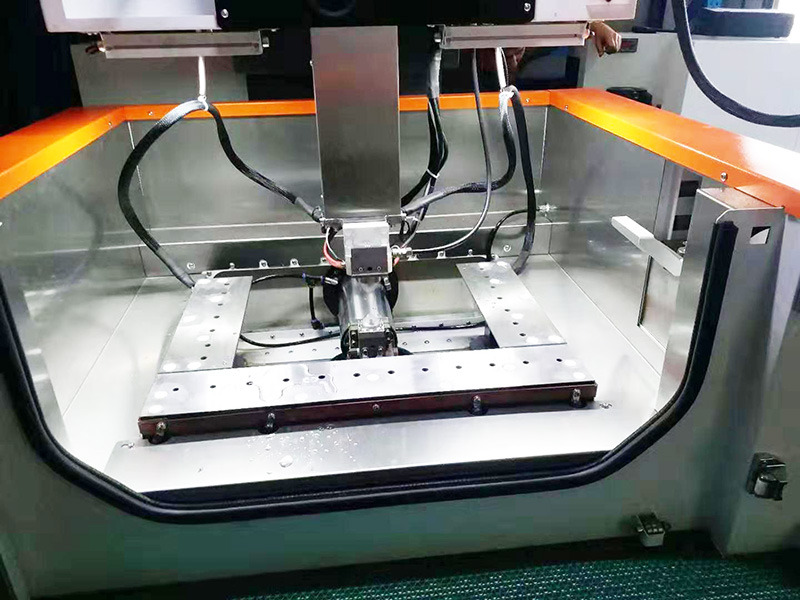

Brass Wire EDM Machine - Wire Cut EDM, Slow Speed Wire EDM Machine For Aluminium extrusion dies

All taiye CNC machine tools are Special design for Aluminium Extrusion dies, Taiye wire cut EDM machine are use the high rigidity and stablity HT250 cast iron base machine, Imported brand servo motor, bearing and screw, the machine tools not only use for Aluminium Extrusion dies , it also suitable for 3C electronic products, automobile molds, hardware molds, and other wire cutting processing.

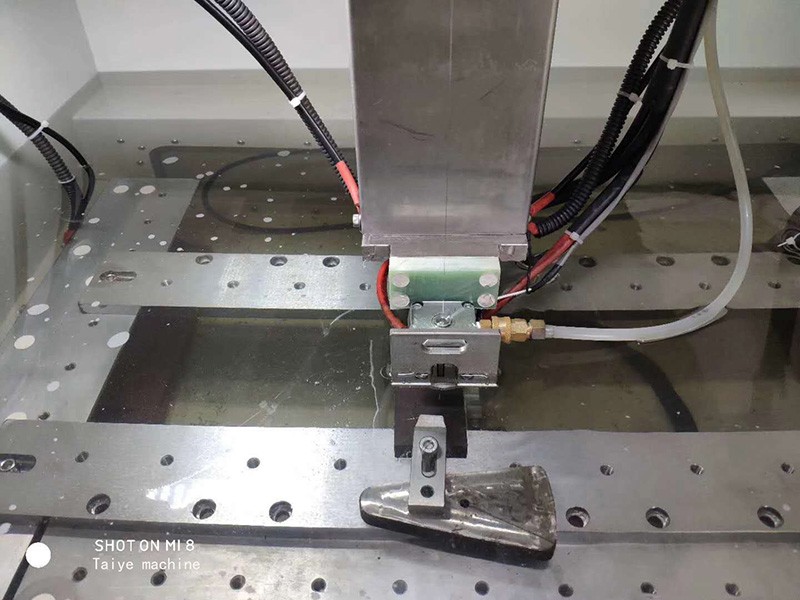

Taiye Brass Wire cut EDM machine tools are uses a copper wire electrode with a diameter of 0.02-0.3mm to generate pulsed discharge in deionized water, which corrodes the workpiece. Compared to molybdenum wire EDM machine tools, Taiye Brass Wire Cut EDM machine tools are include:

Wire speed: 300 mm/sec

Processing accuracy: maximum ± 0.001mm

Surface quality: Ra can reach 0.05 μ m after multiple cuts

Style | 4032 CNC Wire EDM Machine | |

AXIS travel(LXWXH) | mm | 400*320*220 |

Axis Movement | mm | 10*10 |

Max workpiece size (Width X Depth X hight) | mm | 725* 600* 215 |

Max workpiece weight | mm | 300kg |

X/Y feeding speed | mm/min | 1500 |

Wire diameter | mm | 0.15-0.3 |

Max wire feed speed | mm/sec | 300 |

Wire tension | mm | 300-2500(gf) |

Filtration capacity | mm | 650L |

Filtering method | Paper net | |

Ionic resin filter | L | 14L |

Water quality control | Auto | |

Liquid temperature control | Auto | |

Max output current | A | 25A |

Current selection | 10 | |

Rest time | 50 | |

Input | USB,LAN | |

Screen display | 10inch color | |

Control axis number | X,Y,U,V,Z(5Axis),6th axis optional | |

Setting unit | mm | 0.001mm |

Max instruction value | mm | ±9999.999mm |

Round magnification | 0.001-9999.999 | |

Processing condition memory | 1-100 | |

Max power consumption | 3Phase 220±5%/11KVA(Or designated industrial voltage by the customer's country) | |

According to data from the China Machine Tool and Tool Industry Association, the number of slow wire equipment in China will exceed 28000 units in 2023, accounting for 43% of its application in the mold industry. With the implementation of the "Made in China 2025" technology roadmap, the localization rate of precision machining equipment is expected to reach 70% by 2025.